Grandwin Advocates for the Essential Use of Protective Film on Aluminum Components

In the ever-evolving landscape of manufacturing, Grandwin is taking a stand on the critical importance of applying protective film to aluminum profiles and plates. This fundamental practice plays a vital role in ensuring the durability and integrity of aluminum products.

Protective Film as a Safeguard

Grandwin stresses that protective film acts as a crucial barrier for aluminum materials during various stages, including transportation, storage, and processing. This film effectively prevents damage from scratches, corrosion, and contaminants, while also protecting against oxidation, which can compromise the aluminum's appearance and quality.

Broad Industry Applications

The application of protective film is essential across numerous sectors, including construction, automotive, electronics, and furniture. Grandwin is committed to providing high-quality aluminum products that meet the stringent demands of these industries, where precision and surface quality are paramount.

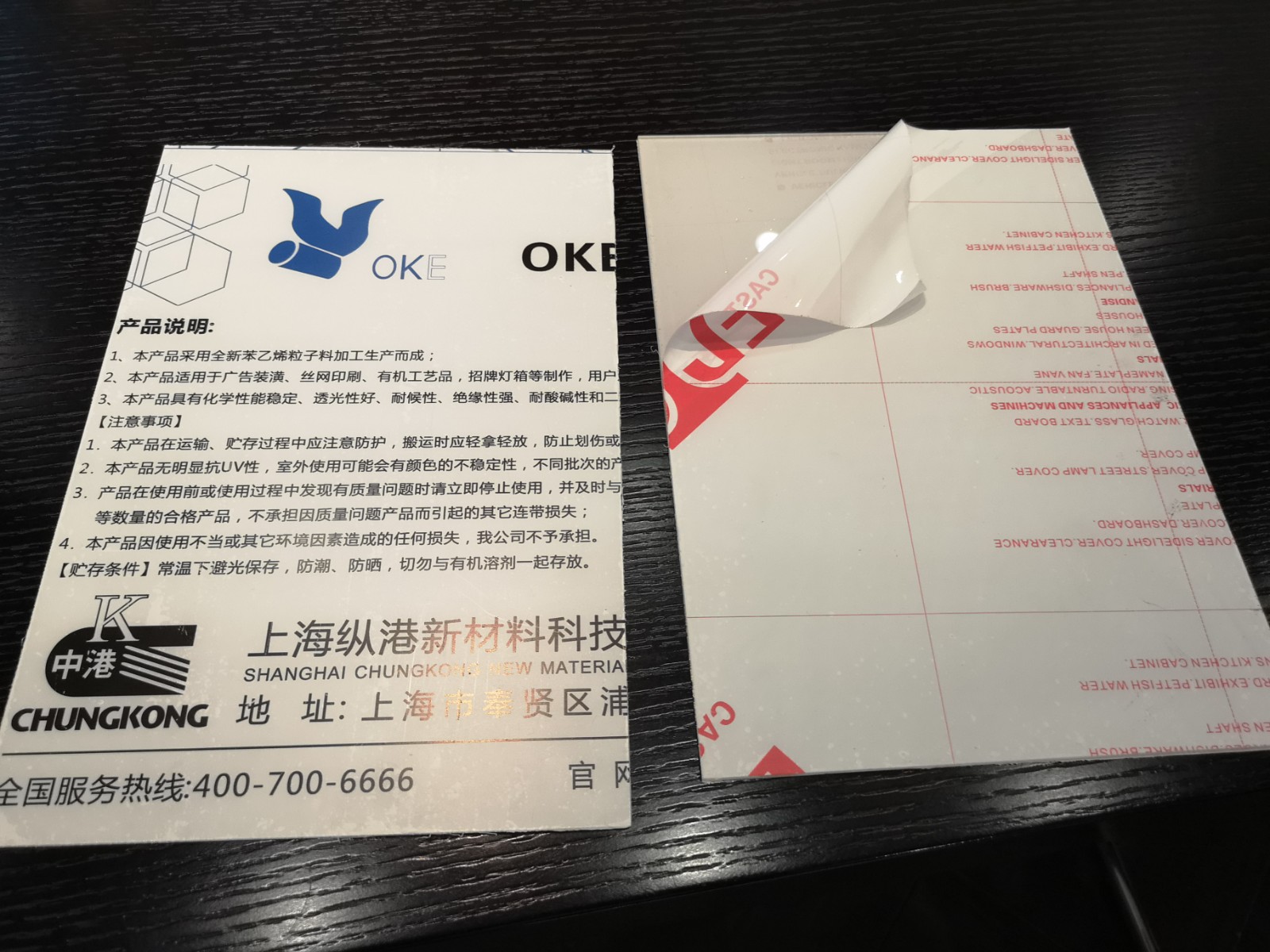

Diverse Options for Protective Films

At Grandwin, a variety of protective films are available to cater to different customer requirements. Options such as polyethylene (PE), polyester (PET), and polyvinyl chloride (PVC) allow clients to select the ideal film based on their specific environmental conditions and application needs.

Important Considerations for Selection

When choosing a protective film, Grandwin recommends evaluating factors such as adhesion strength, resistance to environmental factors, temperature tolerance, and ease of removal. Ensuring that the film does not leave adhesive residue or damage the surface upon removal is essential for maintaining the aluminum's quality.

Case Studies Highlighting Real-World Impact

Grandwin shares insightful case studies that illustrate the negative consequences of not using protective film. Instances of significant product damage and financial losses highlight the necessity of implementing protective measures in manufacturing processes.

Conclusion

For businesses aiming to enhance the quality and longevity of their aluminum profiles and plates, Grandwin firmly advocates for the application of protective film. This essential step not only prolongs product life but also reduces maintenance costs, solidifying its role as a key component in modern manufacturing. Grandwin invites interested parties to connect and explore the protective solutions they offer to meet industry needs.